If you have read any of our recent mountain bike reviews, perhaps you noticed a reference to the SRAM UDH (Universal Derailleur Hanger). As it exists right now, the UDH is simply what it says it is: a universal derailleur hanger standard used across brands and bikes. Brands can equip their bike with one derailleur hanger and shops only need to stock one derailleur hanger. Carry a spare UDH and it’ll fit your bike and your friend's bike, even if you’re riding a Specialized Stumpjumper Evo and they’re riding a Niner Jet 9 RDO.

This is a huge improvement. It used to be that most brands—and sometimes even every model within a brand—utilized its own, unique replaceable hanger. This led to an almost unchecked proliferation of hangers—the site derailleurhanger.com lists more than 780 different hangers.

But a UDH would be just one more hanger to pick from unless it became widely adopted. Thankfully, the UDH was. According to SRAM’s UDH finder tool, more than 30 brands currently utilize the UDH, and many of those brands use it for several models. Norco, for example, has nine UDH-equipped models. At this point, when a new mountain bike launches, I expect it to be UDH-equipped.

More From Bicycling

While industry-wide adoption of a single derailleur hanger standard has many positives for riders (and the bike shops that service those riders), it’s also a small and very low-tech part. In other words, not the kind of thing a brand would make a huge deal about. Certainly not one that a brand like SRAM would invest many dollars into for branding, awareness, and maintaining a searchable database of UDH-equipped bikes. After all, you can mount a Shimano rear derailleur to a UDH, or something more esoteric like a Rotor or Ingrid. Other than making a few pennies selling UDHs to a diverse swath of brands for a wide range of bikes, what’s in it for SRAM?

The generous view is that someone at SRAM came up with a better derailleur hanger design and “gifted” it to the riding community. And maybe that’s part of it. But there had to be something bigger in the UDH for SRAM.

And there is! There’s a new and potentially better way to attach a rear derailleur to the frame: direct mounting without a hanger. This design first showed up in a SRAM patent application in 2018 (US 20180265169 A1). All existing UDH-equipped bikes are prepared for this mounting standard and it’s a system that, as of December 2020, Shimano probably can’t use because SRAM was granted a patent.

I’m not basing this speculation on a single patent application either. Several of SRAM’s recent patent applications show this same direct mounting system. More recently, Factor—when it launched its new Lando XC and Lando HT mountain bikes—called out on the bikes’ webpages that the UDH allows, “future upgrades to direct mount rear derailleurs.” That call-out has since been scrubbed from the bikes’ product pages.

I believe SRAM planned to drop this new derailleur design on us years ago. But the original timeline was blown up by the pandemic and subsequent supply-chain meltdown. So the initial buzz of speculation about the UDH and the SRAM patent application that appeared in mid- to late-2019—when the first patent application appeared—kinda got washed away.

But recently, I’ve fielded some very cryptic phone calls from SRAM asking about what bikes I’ll be riding this summer. And my contacts across a variety of brands have started to titter with excitement, dropping hints to me about something cool coming soon from SRAM that’s somehow related to the UDH. Which caused a little buzz in the back of my head as I began to recall that there was once more to the UDH than just a friendly universal derailleur hanger standard.

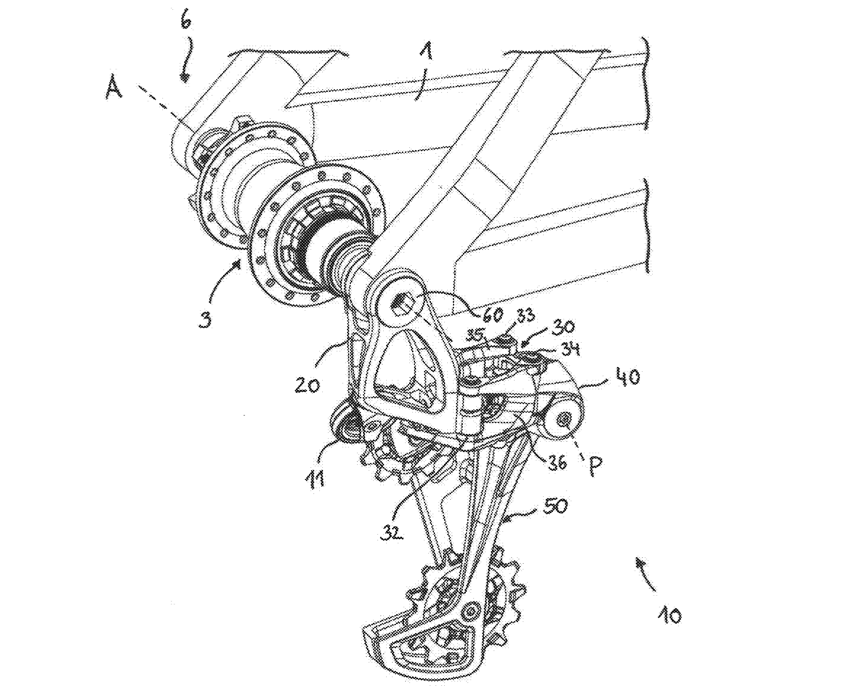

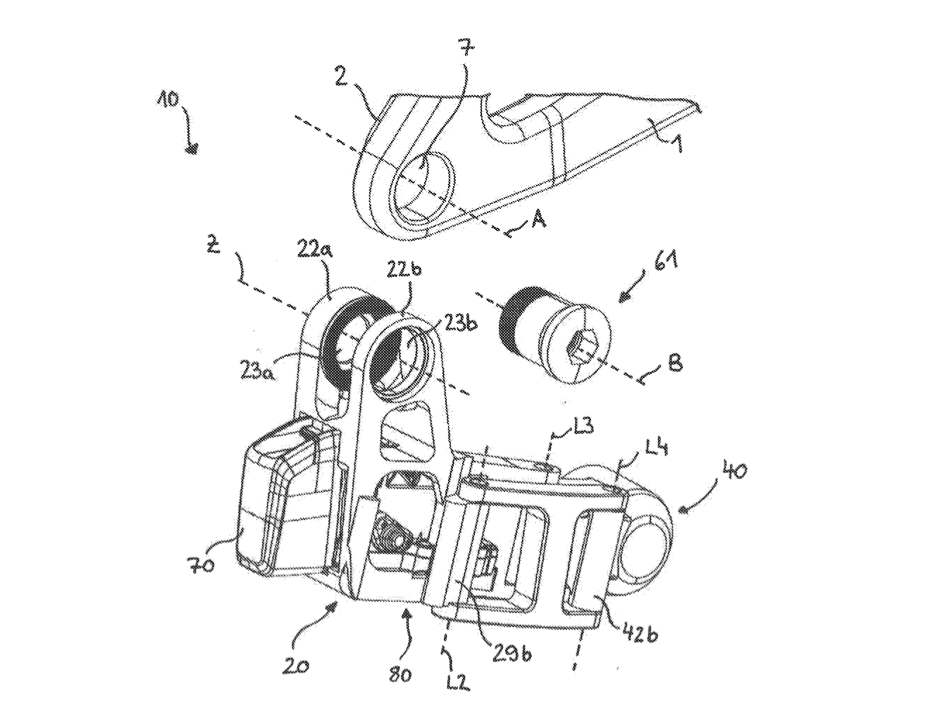

Well then, what is it? It's directly mounting the rear derailleur to the frame without a hanger. Essentially, the UDH was created to lay the groundwork for SRAM to kill the traditional rear derailleur mounting system. The pictures that accompany this article are the best way to understand what’s going on, but here’s my description:

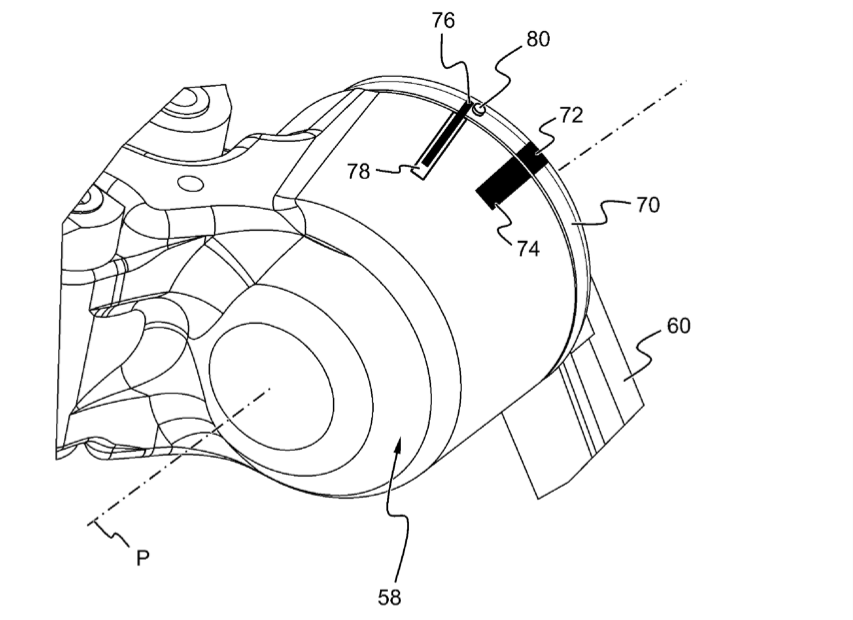

The rear derailleur is coaxially mounted to the frame’s rear thru axle assembly. In place of a traditional mounting bolt, the derailleur body has two vertical plates. These plates slide over the rear dropout—one plate on either side—and the derailleur is secured by a bolt and nut that passes through the chainstay. The derailleur mounting bolt serves a second purpose as the thru-axle’s female threads.

I gotta hand it to SRAM: This is a clean and clever design. Only one part of the rear derailleur—the B-knuckle—changes significantly, and it eliminated parts (the one between the frame and rear derailleur), too.

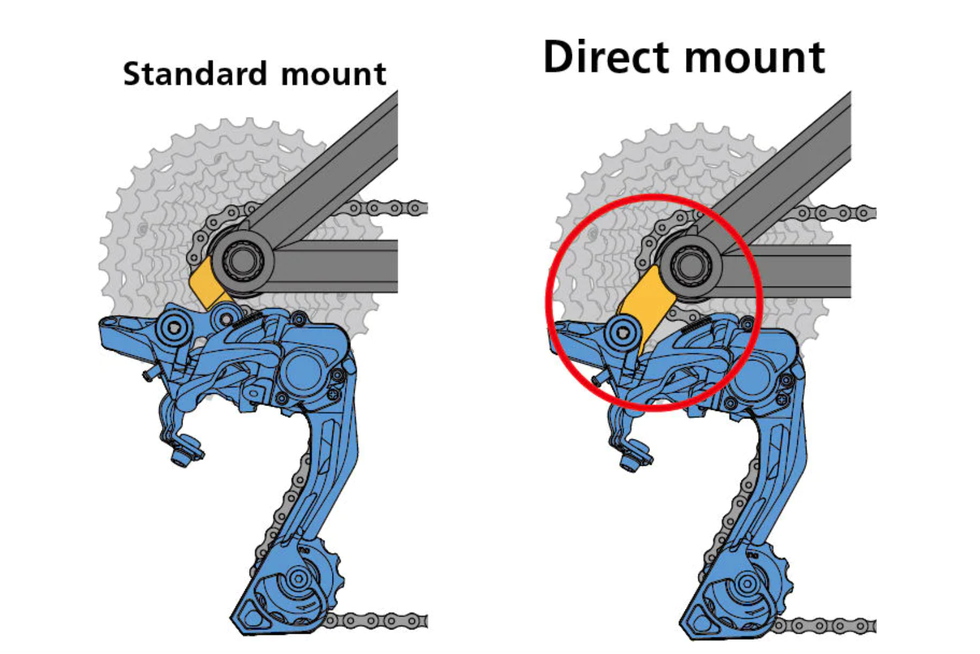

This isn’t the first attempt at a universal derailleur hanger standard, nor the first attempt at direct mounting a rear derailleur. Syntace’s X-12 system, launched in 2013, was one attempt to standardize and improve the rear derailleur hanger. It gathered some interest, but never broke through and achieved widespread adoption.

Shimano also has a few “direct mount” systems in its archives. One is found in any of the brand’s rear derailleurs with the Shadow and Shadow Plus design. The derailleur’s standard mounting link gets replaced with a longer and more rearward projecting hanger. However, this “direct mount” system from Shimano still mounts the derailleur to a hanger, and it doesn’t standardize how the hanger attaches to the frame.

Shimano also offered two (Saint and Hone) gravity-specific rear derailleurs that were mounted to the frame via the thru-axle. But a close look at this design also reveals it is simply a standard rear derailleur with a removable mounting knuckle.

What’s the point of SRAM’s direct mount rear derailleur? A lot more stiffness and probably more strength, too. The current method of mounting a rear derailleur—a thin bit of unsupported metal dangling off the frame, and a small-diameter bolt—is all sorts of flimsy. It was okay-ish when rear cogs maxed out at 28 teeth, rear triangles were rigid, and rudimentary shift technology meant we had to soft-pedal through every shift.

But a modern mountain bike drivetrain has a 50-tooth or larger cassette, which requires a long-ass pulley cage. Modern cassette tooth shaping and chain designs let us shift under nearly full power. Electronic shifting moves the chain with tremendous force. And mountain bikes have four, five, or six (or more) inches of rear suspension travel. We’re riding faster and hitting things harder. Plus, e-bikes can throw an additional 500 watts or so into a drivetrain. But that spindly way of attaching the rear derailleur hasn’t evolved in ages. The current rear derailleur/frame interface is one of the only areas of the bike that hasn’t seen a major change in the past decade.

More stiffness and better control of the position of the rear derailleur relative to the cassette should mean much crisper and more reliable shifting with current cassette sizes and would be beneficial if cassettes get even bigger. Plus, the improved precision and reliability will be necessary if SRAM starts cramming still more cogs—13, 14, and beyond—onto the cassette. That’s because more cogs are usually accompanied by thinner chains, tighter tolerances, and less forgiveness in the system.

I expect that SRAM will initially roll this technology out on high-end drivetrains—probably in a group with other new updates (13-speed? 54-tooth cassettes?)—with their lower-end mechs continuing to mount to frames traditionally. The technology will eventually trickle down. So even if you buy a new bike with a lower-end SRAM group, you can upgrade to SRAM’s latest and greatest if the frame has the UDH.

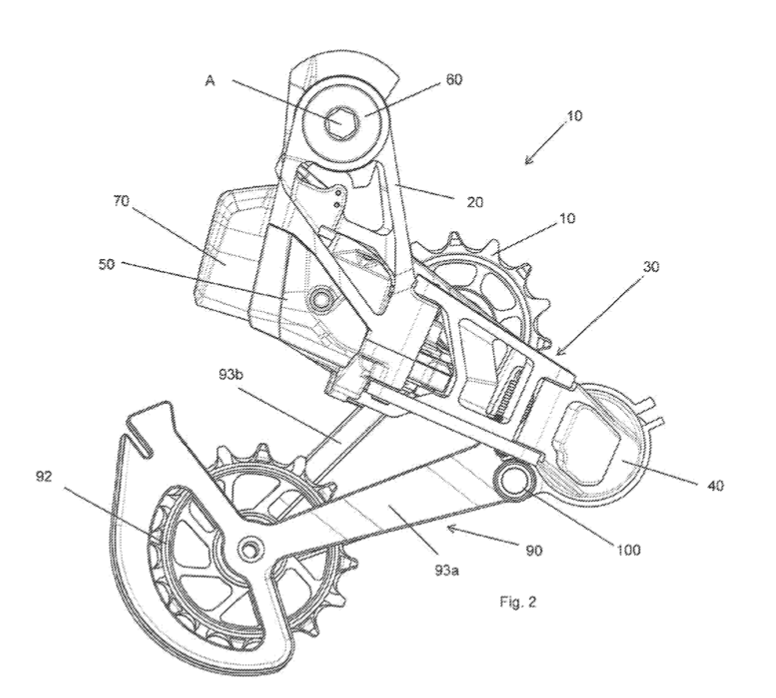

There are other interesting things related to rear derailleurs in the SRAM's patent applications. The direct mount patent application mentions compatibility with 12mm or 15mm rear thru-axles. (Stiffer, stronger 15mm rear thru-axles would be beneficial to e-bikes and DH bikes but might not be compatible with 10-tooth cogs.) Some of SRAM’s other patent applications hold more clues to what might be coming, too. A patent application from February 25, 2021 (US 20210054929 A1) shows a B-gap setup tool built into the derailleur, a “rotation angle detection device which is designed to detect and/or display an angle of rotation between the P-knuckle assembly and the cage assembly.”

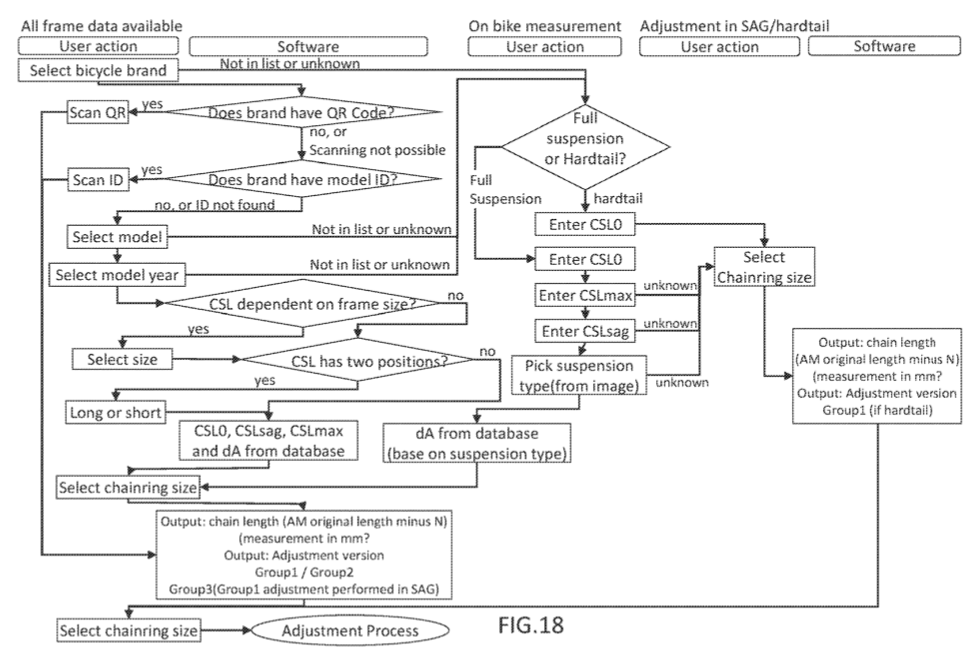

A more recent patent application titled “Electromechanical Derailleur for Coaxial Assembly” (March 3, 2022, US 20220063763 A1) shows a multi-position “blocking device” (like SRAM’s current cage lock, but with more positions), and lays out an app routine to help a user properly size a chain and dial in the correct B-gap.

And there are questions: Will this come to road bikes? Does it have a fuse or breakaway part to protect the frame and derailleur (other than the rearward rotation carried over from the UDH, which seems to be part of the direct mount derailleur patent)? Is the direct mount B-knuckle replaceable or interchangeable with a standard-mount B-knuckle?

Time will reveal all. But a new—and probably better, though there are certain to be headaches—way of mounting a rear derailleur to a bicycle will arrive soon.

A gear editor for his entire career, Matt’s journey to becoming a leading cycling tech journalist started in 1995, and he’s been at it ever since; likely riding more cycling equipment than anyone on the planet along the way. Previous to his time with Bicycling, Matt worked in bike shops as a service manager, mechanic, and sales person. Based in Durango, Colorado, he enjoys riding and testing any and all kinds of bikes, so you’re just as likely to see him on a road bike dressed in Lycra at a Tuesday night worlds ride as you are to find him dressed in a full face helmet and pads riding a bike park on an enduro bike. He doesn’t race often, but he’s game for anything; having entered road races, criteriums, trials competitions, dual slalom, downhill races, enduros, stage races, short track, time trials, and gran fondos. Next up on his to-do list: a multi day bikepacking trip, and an e-bike race.